2021-09-15

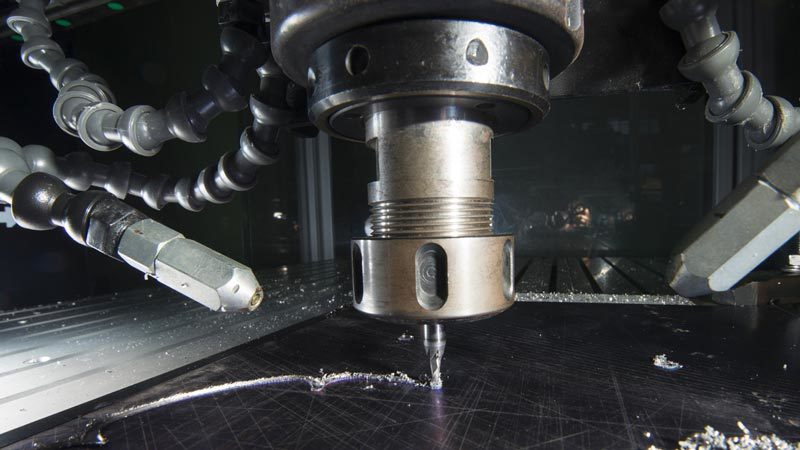

What is CNC machine?

CNC machining manufactures parts by declining manufacturing. Such processing is basically to remove the material from the solid blank and finally form the necessary shape. Milling, turning, polishing, drills can be done by the above method. The incrementing process is an inverse process, and there is no additional material, and finally, a part, for example, 3D printing is formed.

2021-09-15

Factors affecting CNC processing costs

Facility cost occurred before the machining process started. However, the equipment machine belongs to the production reserve cost and ultimately affects the cost of the processing plan. The higher the cost of obtaining, manipulating and maintaining machinery, the higher the parts manufactured by this machine.

2021-09-15

What do you pay attention to the surface treatment of sheet metal custom processing products?

Strictly perform first inspection, intermediate extraction and final inspection. The work size of the workpiece is inspected based on the drawing or process file, the punch edge must not stretch and bend, and the height of the burr must not exceed 10% to 15% of the material thickness.

2021-09-15

What is the general material commonly used in sheet metal working?

It is well known that sheet metal processing is a market that accounts for one-third of the metal processing industry, but what is the material often seen in sheet metal working? I want to introduce the editor of the sheet metal custom processing easily and spread the knowledge.

2021-09-15

Why crack after bending of precision sheet metal

Currently, sheet metal processing has various machining processes throughout the production process, such as sheet metal forming, bending, forming, and assembly. In order to make a complete sheet metal custom processing product, it is necessary to pass the connection process generally, but what is the connection method of the sheet metal working product?

2021-09-15

Low definition casting machine

Low pressure casting makers believe that gravity casting is widely applied in our daily life, and that high quality products make consumers more reliable. Metal gravity casting technology is widely applied worldwide. Compared with other casting processes (such as low pressure casting) at the same production scale, it embodies the overall investment economy and provides greater productivity with relatively small investments.